When it comes to frying food, using the right kind of oil is essential to achieving the best results. Fryer oil plays a crucial role in achieving the perfect texture, taste, and appearance of fried foods. It not only affects the flavor of the food, but also contributes to the overall quality and safety of the cooking process.

There are several factors to consider when choosing the best fryer oil. The smoke point is one of the most important considerations, as it determines the temperature at which the oil begins to degrade and release harmful compounds. Additionally, the oil’s flavor, cost, and health benefits are also important factors to consider.

One best practice for fryer oil is to regularly filter and replace it. As oil is used, it can become contaminated with food particles, which can affect the taste and quality of the fried food. Regularly filtering the oil helps remove these particles and extend its lifespan. It is also important to monitor the oil’s temperature and avoid overheating, as this can cause the oil to break down faster and produce undesirable flavors.

The Importance of Quality Fryer Oil

Fryer oil is a crucial component in any kitchen that uses a fryer. It plays a significant role in determining the taste, quality, and safety of fried foods. Using high-quality fryer oil is essential to achieve the best results and maintain a high standard of food preparation.

One of the primary reasons why quality fryer oil is important is its impact on the taste of fried foods. Fresh and clean fryer oil enhances the flavor and allows the natural taste of the food to shine through. On the other hand, old or low-quality oil can give off unpleasant and rancid flavors, affecting the overall enjoyment of the dish.

Furthermore, using quality fryer oil is crucial for maintaining food quality and safety. Fresh oil has a higher smoke point, which means it can withstand higher cooking temperatures without breaking down. This not only helps in achieving a desirable texture and appearance, but it also reduces the likelihood of the oil becoming rancid or producing harmful substances during the frying process. Regularly monitoring and changing the fryer oil is essential for preventing the accumulation of harmful compounds and ensuring food safety.

In conclusion, quality fryer oil is vital for achieving delicious and safe fried foods. Its impact on taste, appearance, and safety make it a crucial ingredient in any kitchen that uses a fryer. Regularly monitoring and replacing fryer oil with fresh, high-quality options is essential for maintaining the highest standards in food preparation.

Choosing the Right Type of Fryer Oil

When it comes to frying, the type of oil you choose can greatly impact the taste, texture, and overall quality of your fried foods. With so many options available, it is important to understand the characteristics and benefits of different types of fryer oil before making a decision.

1. Smoke Point: One of the most important factors to consider when choosing fryer oil is its smoke point. The smoke point is the temperature at which the oil starts to break down and produce smoke. Oils with higher smoke points are ideal for deep-frying as they can withstand higher temperatures without burning or affecting the flavor of the food.

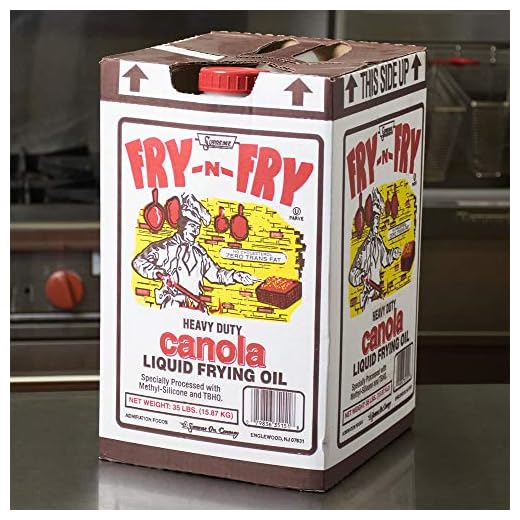

- Canola Oil: With a high smoke point and a neutral flavor, canola oil is a popular choice for deep-frying. It is versatile and can be used for a wide range of deep-fried foods.

- Peanut Oil: Known for its high smoke point and rich flavor, peanut oil is often used in Asian cuisine. It adds a distinct nuttiness to fried foods.

- Sunflower Oil: Another oil with a high smoke point, sunflower oil is known for its light flavor. It is a good option for frying foods that require a higher heat.

2. Flavor: The flavor of the oil can greatly enhance the taste of your fried foods. Some oils, like peanut oil and sesame oil, have distinct flavors that can complement certain dishes. Others, like canola oil and sunflower oil, have more neutral flavors that allow the natural flavors of the food to shine.

3. Nutritional Content: While deep-fried foods are not typically associated with health, choosing the right type of fryer oil can make a difference in the nutritional content. Oils that are high in monounsaturated fats, such as canola oil and peanut oil, are considered healthier options.

In conclusion, when selecting fryer oil, it is important to consider its smoke point, flavor, and nutritional content. Experimenting with different types of oil can help you achieve the perfect fried foods that are both delicious and satisfying.

Proper Storage and Handling of Fryer Oil

Proper storage and handling of fryer oil are essential to maintain its quality and prolong its usability. By following best practices, businesses can minimize wastage and ensure the safety and consistency of their fried food products.

1. Storage containers: Choose appropriate storage containers for fryer oil, such as stainless steel or food-grade plastic containers. These containers should have a tight-fitting lid to prevent exposure to air and contaminants.

2. Temperature control: Store fryer oil at a cool and dry place, away from direct sunlight and heat sources. Excessive heat can cause oil to break down more quickly, reducing its frying capabilities and affecting the taste and texture of food.

3. Cleanliness: Before transferring oil to a storage container, ensure that it is free from any debris, crumbs, or moisture. Contaminants in the oil can lead to off-flavors and compromise the quality of the fried food.

4. Filtering: Regularly filter fryer oil to remove food particles and impurities that accumulate during frying. This practice helps maintain the oil’s clarity and extends its lifespan, resulting in better tasting fried food.

5. Rotation: Implement a first-in-first-out system to ensure the use of older oil before newer batches. This practice prevents the oil from becoming rancid and minimizes any potential negative impact on the quality of the fried products.

6. Labeling: Clearly label storage containers with the date of oil preparation or filtering. This information helps in tracking the oil’s age and ensures that it is used within its recommended shelf life.

7. Safe handling: When handling fryer oil, use appropriate protective equipment, such as gloves, to prevent burns and spills. Carefully pour oil into the fryer to avoid splashing and maintain a clean work area to prevent slips and falls.

By practicing proper storage and handling techniques, businesses can maximize the efficiency and longevity of their fryer oil, leading to high-quality fried food products and customer satisfaction.

Regular Maintenance and Filtering of Fryer Oil

Regular maintenance and filtering of fryer oil is crucial to ensure the quality of fried food and to extend the lifespan of the oil. By consistently performing these tasks, businesses can avoid the negative effects of degraded oil, such as off-flavors and decreased frying efficiency.

One best practice is to regularly check the temperature of the fryer oil. Monitoring the temperature helps control the oil’s breakdown rate and prevents it from reaching its smoking point. Maintaining the oil at an optimal temperature ensures that the food is fried evenly and reduces the formation of harmful compounds.

- To maintain the oil’s quality, it is important to filter it regularly. Filtering removes food particles, crumbs, and other contaminants that can accelerate the oil’s degradation. This process can be done using a filtration system or through a manual process of straining the oil.

- Another important aspect of maintenance is regular skimming. Skimming involves removing any excess floating debris or crumbs from the fryer. By doing this, businesses can prevent the buildup of burnt or degraded particles in the oil, which can negatively impact the taste and quality of the fried food.

- Performing a visual inspection of the oil is also necessary. This can help identify any signs of degradation, such as discoloration or the presence of a burnt smell. If any such signs are observed, it is important to replace the oil to maintain the quality and taste of the fried food.

- Lastly, keeping the fryer clean and ensuring that it is not overcrowded with food can significantly contribute to the maintenance of the oil. Regularly cleaning the fryer and avoiding overcrowding help prevent the oil from overheating and deteriorating more rapidly.

By following these best practices for regular maintenance and filtering of fryer oil, businesses can ensure that their fried food remains delicious and of high quality, while also maximizing the lifespan of their oil. Consistency in these practices will not only enhance the taste and appearance of the fried food but also help in achieving cost savings by reducing the frequency of oil replacement.

Monitoring Oil Quality and Replacement Time

Monitoring the quality of fryer oil is crucial in maintaining the taste and quality of fried foods. Regularly checking the oil for signs of degradation, such as excessive foaming, dark color, and off-putting odor, is essential to ensure that only fresh, high-quality oil is used for frying. Additionally, measuring the temperature of the oil during frying can help identify any variations that may affect the frying process.

The replacement time for fryer oil can depend on various factors, including the type of food being fried, the frequency of frying, and the temperature at which the oil is heated. It is recommended to follow the manufacturer’s guidelines for oil replacement as they may have specific recommendations based on the fryer model. Implementing a regular oil change schedule can help maintain the quality of the food and extend the lifespan of the fryer equipment.

To assist in monitoring oil quality and replacement time, it is beneficial to keep a log that records the start and end time of each frying session, as well as the temperature and condition of the oil before and after frying. This log can help identify any patterns or trends in oil degradation and assist in determining the optimal replacement time for the oil.

Proper maintenance of fryer equipment, such as regular cleaning of filters and debris removal, can also contribute to prolonging the life of the fryer oil. Additionally, using a food-grade oil stabilizer or filtration system can help remove impurities and extend the usability of the oil.

By closely monitoring oil quality and replacement time, and implementing best practices for maintenance, establishments can ensure that they consistently deliver high-quality, delicious fried foods to their customers.

Safe Disposal of Used Fryer Oil

Fryer oil should never be disposed of down the drain or in regular garbage bins as it can cause significant environmental damage. There are several safe and responsible methods for disposing of used fryer oil that should be followed to ensure proper waste management.

1. Recycling Centers

One of the best ways to dispose of used fryer oil is by taking it to a local recycling center. Many recycling centers have specific containers or collection points for used cooking oil. The oil can then be recycled and repurposed for various purposes such as biodiesel production or animal feed. Check with your local municipal waste management or recycling center for the nearest drop-off location.

2. Donation

In some cases, used fryer oil can be donated to local farms or animal shelters. Some farmers use used cooking oil as a supplement for animal feed, particularly for pigs or poultry. Contact your local farmers or animal shelters to see if they accept donations of used cooking oil. This can be a responsible and sustainable way of disposing of the oil while helping out the community.

3. Professional Collection Services

There are professional collection services available that specialize in the proper disposal of used fryer oil. These services often provide containers or drums for storing the oil, and they regularly visit establishments to collect the used oil. They ensure that the oil is disposed of in an environmentally friendly manner, such as through recycling or proper treatment at specialized facilities.

In conclusion, it is crucial to dispose of used fryer oil safely and responsibly to prevent environmental damage. Recycling centers, donation to local farms or animal shelters, and professional collection services are some of the best methods for proper oil disposal. By following these practices, we can contribute to a cleaner and greener environment.

10 Best Practice Fryer Oil

Features

| Release Date | 2013-10-02T00:00:01Z |

| Size | 35 Pound (Pack of 1) |

| Publication Date | 2013-10-02T00:00:01Z |

Features

| Part Number | 175-1081 |

| Model | 175-1081 |

| Color | Silver |

Features

| Part Number | BAN-Yiyiring-0783 |

| Model | BAN0783 |

| Color | Dark Blue |

| Size | 6 Gal |

FAQ

What is the best way to dispose of used fryer oil?

The best way to dispose of used fryer oil is to recycle it. You can collect the oil in a container and then take it to a local recycling facility or a designated drop-off location.

Can you pour used fryer oil down the drain?

No, you should never pour used fryer oil down the drain. It can clog the pipes and cause blockages in the sewage system. It’s important to dispose of it properly to prevent any potential damage.

What should I do if there are no recycling facilities nearby?

If there are no recycling facilities nearby, you can dispose of the used fryer oil in a sealed container and throw it in the regular trash. Make sure to check with your local waste management authorities for any specific guidelines or regulations regarding the disposal of cooking oil.

Can I reuse used fryer oil?

Yes, you can reuse used fryer oil multiple times if it is properly filtered and cleaned. After each use, strain the oil through a fine-mesh strainer or cheesecloth to remove any food particles. Store the filtered oil in a clean, airtight container and keep it in a cool, dark place. However, keep in mind that the oil will eventually break down and lose its quality, so it’s important to monitor its condition and discard it when necessary.

Conclusion

In conclusion, the safe disposal of used fryer oil is crucial for both environmental and safety reasons. Improper disposal can result in pollution of waterways and harm to wildlife. Therefore, it is important to follow proper guidelines for disposing of used fryer oil, such as allowing it to cool, straining out any large debris, and storing it in a leak-proof container. Additionally, recycling fryer oil can greatly reduce its impact on the environment by converting it into biodiesel. By taking these steps, individuals can contribute to a cleaner and safer environment for future generations.